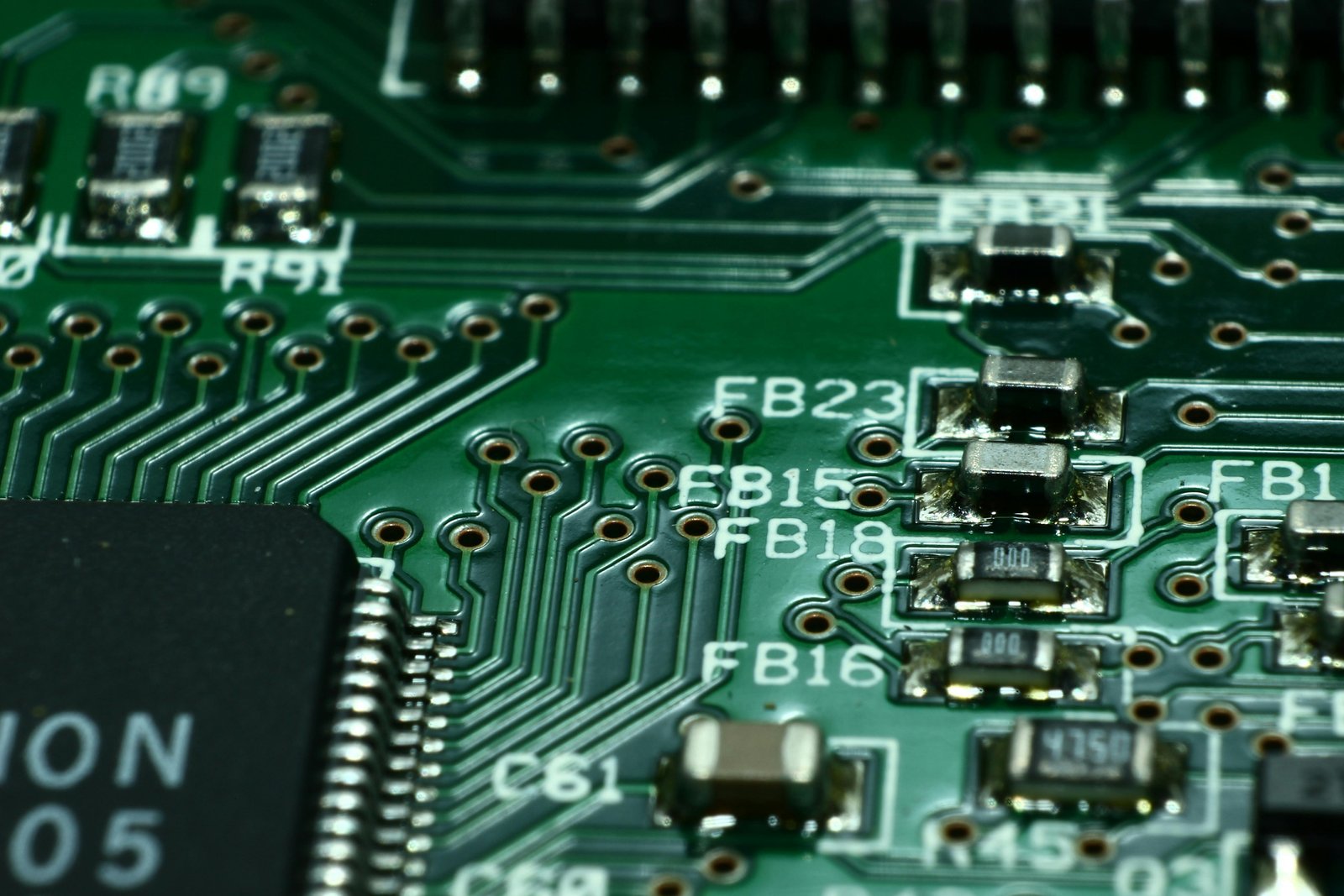

Metals manufacturing is a complex process that involves the use of various equipment and machinery, including electrical components such as reactors. Reactors are important in metals manufacturing as they help control the flow of electricity and protect equipment from power surges and other electrical issues.

Category : | Sub Category : Posted on 2025-11-03 22:25:23

One key concept in understanding the role of reactors in metals manufacturing is electrical reactance. Electrical reactance is the opposition that electrical components, such as reactors, offer to the flow of alternating current (AC) in a circuit. It is measured in ohms and is denoted by the symbol X. There are two types of electrical reactance: capacitive reactance and inductive reactance. Capacitive reactance occurs in circuits that contain capacitors, while inductive reactance occurs in circuits that contain inductors, such as reactors. In metals manufacturing, reactors are used to control the amount of electrical current flowing through a circuit. By introducing inductive reactance, reactors help regulate the flow of electricity and prevent equipment from overheating or sustaining damage. Reactors also play a crucial role in power factor correction in metals manufacturing. Power factor is a measure of how effectively electrical power is being used in a circuit. A low power factor can result in inefficient energy use and increased electricity costs. Reactors help improve power factor by reducing the amount of reactive power in the circuit, which in turn increases the efficiency of electrical systems in metals manufacturing. In conclusion, electrical reactance and reactors are essential components in metals manufacturing processes. By understanding how electrical reactance affects circuitry and the role of reactors in controlling electrical flow, manufacturers can optimize their operations and ensure the efficient production of metal products. If you are interested you can check https://www.gafam.org

Leave a Comment:

SEARCH

Recent News

- Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

- **The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

- Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

- Vancouver is home to a thriving tech scene, with several companies leading the way in GPU, AI, and electronics innovation. In this article, we will take a look at some of the best companies in Vancouver that are at the forefront of these technologies.

- The UK government has been at the forefront of supporting businesses in various sectors, including electronics and AI, through a range of support programs. One key area where this support is particularly evident is in the development of GPU technology.

- In today's fast-paced technological landscape, the intersection of GPUs, AI, and electronics has revolutionized various industries. Ireland, known for its vibrant tech scene, is home to several top companies at the forefront of this cutting-edge integration. Let's take a closer look at some of the top Irish companies making significant strides in the GPU, AI, and electronics space.

- Tokyo is a hub for top companies in the fields of GPU, AI, and electronics. These companies play a significant role in driving innovation and technological advancements in various industries. Let's take a closer look at some of the top companies in Tokyo in these sectors.

- Tokyo is known for its vibrant startup scene, with numerous companies emerging in various industries, including GPU, AI, and electronics. In recent years, these three sectors have seen a surge in innovation and growth, driven by the increasing demand for advanced technology solutions.

READ MORE

3 months ago Category :

Vancouver is rapidly becoming a hub for innovative startups in the fields of GPU technology, artificial intelligence (AI), and electronics. These industries are thriving in the city, attracting entrepreneurs, investors, and talent from around the world. In this blog post, we will introduce some of the top startups in Vancouver that are making a significant impact in these sectors.

Read More →3 months ago Category :

**The Role of GPUs in Advancing AI Electronics in Vancouver's Import-Export Industry**

Read More →3 months ago Category :

Vancouver has emerged as a thriving hub for the electronics industry, especially in the realm of GPU and AI technologies. Companies in Vancouver are leading the way in developing cutting-edge solutions that leverage the power of GPUs and AI to drive innovation across various sectors.

Read More →3 months ago Category :